| Model | GE9612T-S |

| Capacity | 96×0.2ml |

| Temperature Range | 0~100℃ |

| Max. Heating Rate | 4.5℃/s |

| Max. Cooling Rate | 4℃/s |

| Uniformity | ≤±0.2℃ |

| Accuracy | ≤±0.1℃ |

| Display Resolution | 0.1℃ |

| Temperature Control | BlockTube |

| Ramping Rate Adjustable | 0.1~4.5℃ |

| Gradient Uniformity | ≤±0.2℃ |

| Gradient Accuracy | ≤±0.2℃ |

| Gradient Temp. Range | 30~100℃ |

| Gradient Spread | 1~30℃ |

| Hot Lid Temperature | 30~110℃ |

| Hot Lid Height Adjustable | Stepless Adjustable |

| Number of Programs | 10000 +(USB FLASH) |

| Max. No. of Step | 30 |

| Max. No. of Cycle | 99 |

| Time Increment/Decrement | 1 Sec ~ 600 Sec |

| Temp. Increment/Decrement | 0.1~10.0℃ |

| Pause Function | Yes |

| Auto Data Protection | Yes |

| Hold at 4℃ | Forever |

| Yes | |

| LAN to computer | Yes |

| LCD | 8inch,800×600 Pixels, TFT |

| Communication | USB2.0 , LAN |

| Dimensions | 390mm×270mm×255mm (L×W×H) |

| Weight | 8.5kg |

| Power Supply | 85~264VAC , 47~63Hz , 600 W |

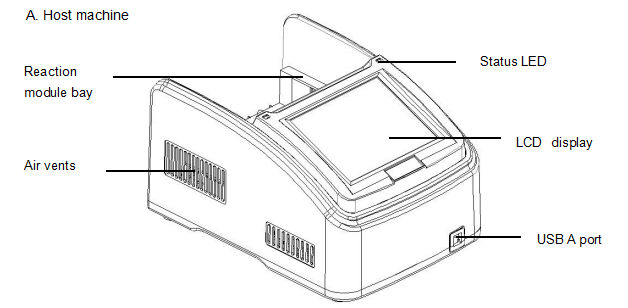

Figure 1. Frontal view of the thermal cycler.

● Reaction module bay — holds inserted reaction module ● Air vents — allows the thermal cycler to cool quickly ● Status LED — indicates status of reaction module ● LCD display — displays operating status ● USB A port — connects to a USB key, computer mouse, or other USB devices

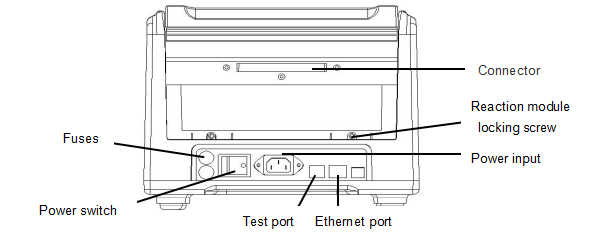

Figure 2. Back view of the thermal cycler.

● Connector — connection between host machine and reaction module ● Reaction module locking screw —locks reaction module ● Test port — for service testing only ● Ethernet port — connects the thermal cycler to a computer

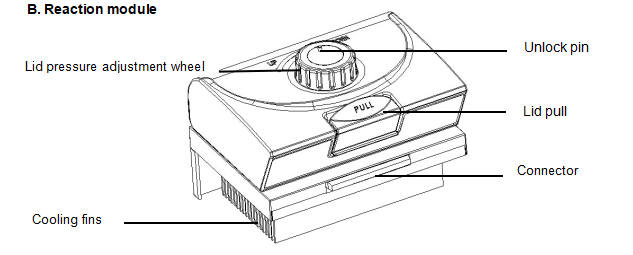

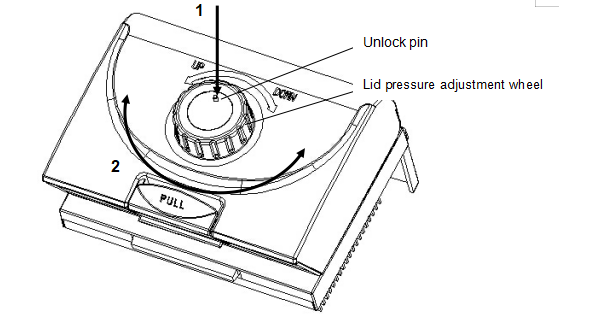

Figure 3. The lid and cooling fins of a 96-well reaction module.

● Lid pressure adjustment wheel — adjust the lid pressure ● Unlock pin — to unlock wheel ● Lid pull — opens and closes the lid ● Connector — connection between host machine and reaction module

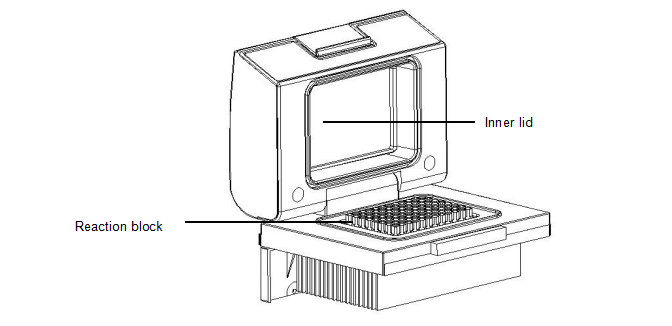

Figure 4. Opening view of a 96-well reaction module.

●Inner lid — maintains the lid temperature to prevent condensation and evaporation ● Reaction block — holds reaction vessels, including tubes and microplatesC. High Performance Smart Lid To achieve optimum pressure on the tubes the GE9612T-S is equipped with a height adjustable heated lid. Close the lid: After the samples have been placed in the block close the lid. Turn the wheel clockwise until you hear a clicking noise. In this mode the pressure will not increase further, even when you keep on turning the wheel. Note: The pressure of the lid has been optimised for a fully loaded block. If only very few Tubes are loaded to the block you should place dummy tubes in the four corner positions to avoid damage of tubes by excessive pressure. Open the lid: First: Release pressure by turning the wheel counter clockwise. As soon as there is no more resistance the pressure has been released. Then: Open the lid with by pushing the front button. Important: The lid should not be opened under pressure because this leads to damage of the locking mechanism.D. Releasing blocked lid wheel Note: When the lid is in the very up or down position, it may happen that the wheel is uncoupled. In this situation the clutch mechanism is active in both directions (clicking noise in either direction). To unlock wheel, press down metal pin with a ball pen and turn wheel carefully. This pin overrides the automatic clutch mechanism. Thus, care must be taken not to apply excessive pressure. Release lid in upper position: 1)press pin 2)carefully turn wheel while holding the pin down CLOCKWISE, until you feel normal resistance (no more clicking noise, clutch is released). Release pin and turn lid down, until the clutch mechanism is activated (clicking noise, optimum pressure applied). Release lid in down position: 1)press pin 2)carefully turn wheel while holding the pin down COUNTERCLOCKWISE, until you feel normal resistance (no more clicking noise, clutch is released). Release pin and turn wheel counter clockwise until pressure is completely released.Open lid. Important: When the clutch mechanism is active (= optimum pressure is applied), do not use pin to further increase lid pressure. This would lead to damage of tubes and instrument !

Release lid in upper position: 1)press pin 2)carefully turn wheel while holding the pin down CLOCKWISE, until you feel normal resistance (no more clicking noise, clutch is released). Release pin and turn lid down, until the clutch mechanism is activated (clicking noise, optimum pressure applied). Release lid in down position: 1)press pin 2)carefully turn wheel while holding the pin down COUNTERCLOCKWISE, until you feel normal resistance (no more clicking noise, clutch is released). Release pin and turn wheel counter clockwise until pressure is completely released.Open lid. Important: When the clutch mechanism is active (= optimum pressure is applied), do not use pin to further increase lid pressure. This would lead to damage of tubes and instrument !